VOLVO

Volvo has made the industry’s most advanced automated manual transmission even better. The latest edition of the Volvo I-Shift transmission includes upgraded hardware and software, greater durability, and a new countershaft brake for improved performance and smoother, faster shifting. The electronic control unit can handle any load and any road, shifting perfectly every time. We’ve also improved clutch durability and torsional dampening in both our D11 and D13 models. So I-Shift not only keeps fuel costs down, it can also help slow driveline wear, reduce noise and vibration, extend transmission life, and lower maintenance costs.

Whether your route includes rolling hills or steep mountain terrain, Volvo’s I-See predictive cruise employs self-learning knowledge of road topography to work with I-Shift, helping your drivers optimize the truck’s speed and gear shifting.

VOLVO NEW I-SHIFT TRANSMISSION

Designed for the most rigorous

on/off-road work in construction and heavy-haul applications, the Volvo I-Shift

for Severe Duty 12-speed automated manual transmission combines the efficiency

and productivity benefits of the Volvo I-Shift with components for even uptime

and component life. Standard on Volvo VHD models, the I-Shift for Severe Duty

features hardened gears and other hardware to help withstand frequent shifting

in rugged operating environments.

STARTABILITY &

MANEUVERABILITY

When startability and maneuverability are critical, the

I-Shift with crawler gears offers the highest weight capacity in an automated

manual transmission. It enables controlled forward and reverse travel at

extremely slow speeds.

The I-Shift with Crawler Gears option adds either one or two

gears to the base 12-speed I-Shift for Severe Duty, a low gear and ultra-low

gear. The 13-speed version has one low crawler gear with a 17.54 to 1 ratio.

The 14-speed version has one low crawler gear with a 19.38 to 1 ratio, and one

ultra low crawler gear with a 32.04 to 1 ratio. The overall ratio of the

I-Shift with Crawler Gears, 41.08 to 1, is more than double that of the

I-Shift.

Volvo’s Selective Catalytic Reduction (SCR) system is a superior solution to the EPA’s emissions standards, not to mention a fuel- and cost-saving innovation for your fleet. Here’s how it works: high-NOx/particulate exhaust flows from the engine to Volvo’s diesel particulate filter (DPF), where much of the exhaust’s particulate is removed. Next, before the exhaust reaches the catalytic converter, diesel exhaust fluid (DEF) is mixed in. The DEF and catalytic converter change the harmful nitrogen oxides into harmless nitrogen and water vapor, and the truck’s NOx emissions register at near-zero levels. DEF allows the engine to use less exhaust gas recirculation (EGR), and maintain higher oxygen levels for better combustion.

.

VOLVO I-SHIFT PRODUCT GUIDE

VOLVO TECHNICAL DATA SHEET

VOLVO BODY BUILDER INSTRUCTIONS

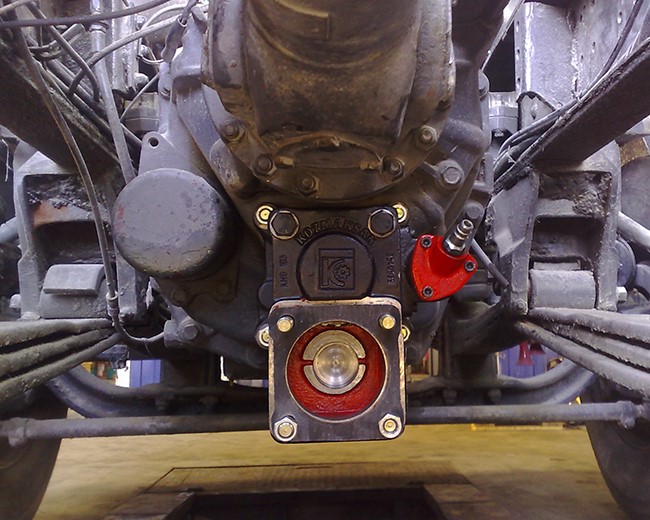

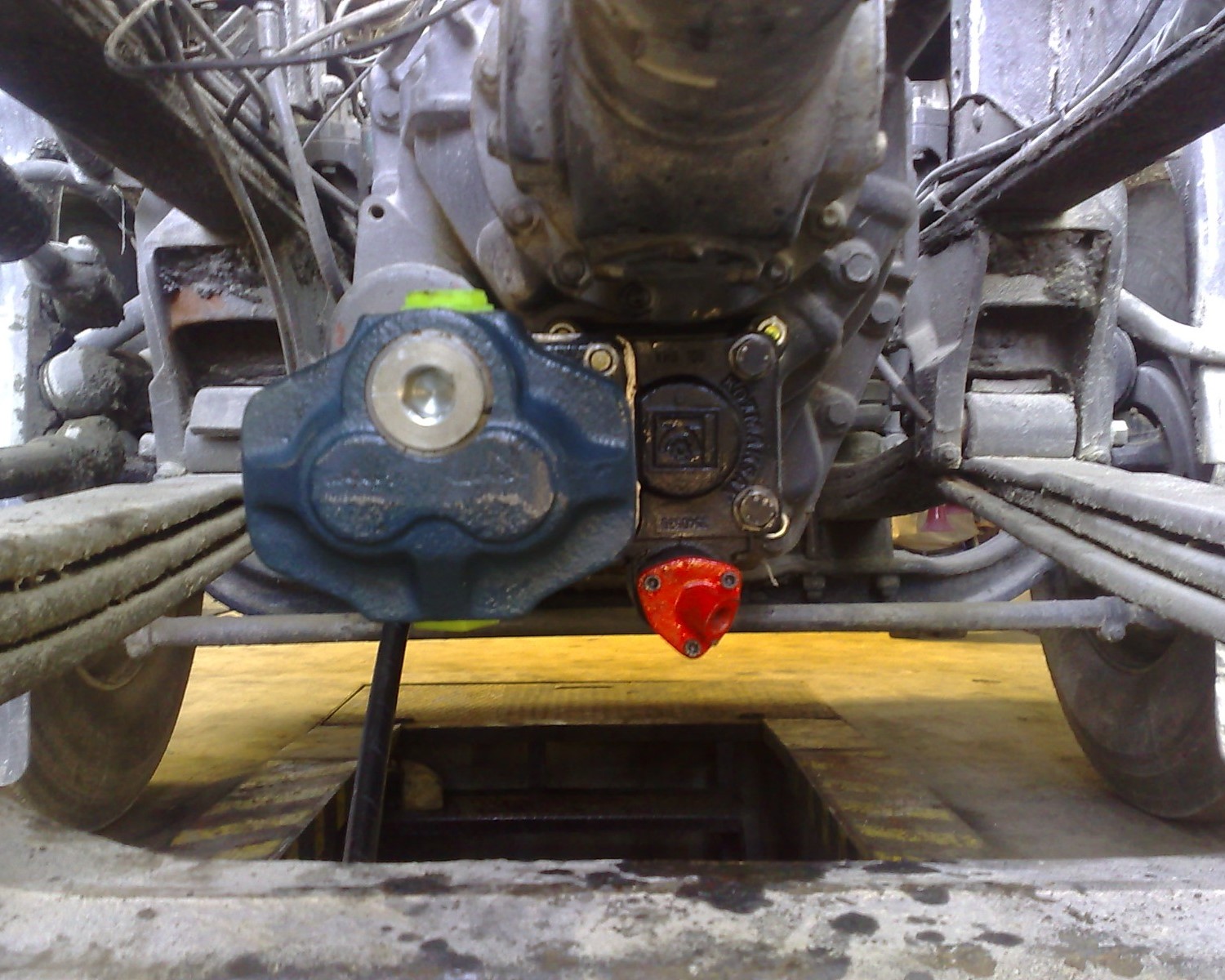

VOLVO POWER TAKE-OFFS AND HYDRAULIC PUMPS

FACE SHEET OF VOLVO PTR-FH POWER TAKE-OFF (PTO)

VOLVO Gearbox mounted power take-off,

PTR - FL / PTR - FH / PTR-D / PTR - F / PTR - DM / PTR - DH / PTRD - F / PTRD - D / PTRD - D1 / PTRD - D2 /